THE PAPER TRADE AND PRINTING

from East London Industries, by William Glenny Crory.1

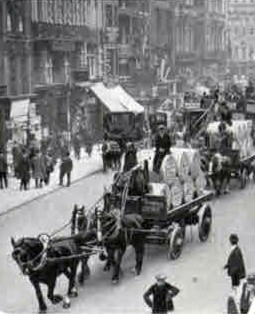

One of the most valuable branches of commerce in, the United Kingdom is that known as the “Paper Trade.” It has many branches, and several of these are represented in East London. There is paper-making, printing, lithographing, and paper-bag making done to a sufficient extent East of Aldgate Pump to deserve a prominent place each as an Industry of the locality.

For my facts I have visited Mr. Edward Lloyd‘s paper mills. Bow, where paper is extensively manufactured; and also the Works of Mr. A. T. Roberts, Hackney-road, which is one of the places where a considerable quantity of printing is done. Had I attempted to go fully into the paper trade in East London, I should have noticed Messrs. Thomas Farrens and Co.‘s mills at Ilford; also paper-bag making, as carried on by Mr. Pitt, Leman-street; Mr. Brandon Jones, Devonshire- square, and other in that line, as well as the publishing of newspapers. But I must pass most of these over without further mention, taking Mr. Lloyd as representative in his line, and Mr. Roberts as a fair specimen of those in the lithographic and letter-Press printing business. If I mentioned printers of newspapers I should, in common justice, place the East London Observer as decidedly foremost of all in the locality in its special work. I should also be constrained to state, that in every respect it has steadily progressed for many years; but within a very short period, it has increased in circulation, as well as improved in typography, and in the quality of the paper on which it is printed.

When I called at Lloyd‘s mill, I was most courteously received by Mr. Frank Lloyd, who showed me over the premises. Mr. Edward Lloyd is not only an employer of labour in East London, but is also a merchant in the Esparto line. He brings his supplies of this valuable fibre chiefly from Algeria, where he has establishments in connection with his East London business, namely, at Blockhaus d‘Orleans, Oran, and Oned Magoun, Arzew. He has places for gathering Esparto at Calle de la Marina Espanola, Cartagena; Almeria and Aguilas in Spain. The gathering and utilising of this plant is a most important enterprise, on public grounds, and Mr. Edward Lloyd has made his mark in connection with Esparto even more clearly than as a paper manufacturer, printer, or newspaper proprietor.

The mill premises at Bow cover some ten acres; and one of the most interesting sights is the stacks of Esparto piled up, ready to be made into paper. This fibre costs considerably more than wages in gathering it. It takes a long time to go out of the soil, and produces annually; and when it is in a sickly state, burning is good for it. It sells f.o.b. in the Thames at a figure which makes it a formidable rival to straw in paper-making. But it needed all that energy for which Mr. Lloyd is remarkable to bring a trade so difficult of management into that state of efficiency in which the Esparto branch now is. This fibre is supplied to paper-makers all over the United Kingdom. Doubtless there are several other foreign fibrous plants and woods, which would suit well for making paper; but, except this, none of them has yet been largely, if at all to any noticeable extent, imported. The cost of freight is too high; and this is owing to bulk in proportion to weight. The bales of Esparto to be seen here are done up in iron hoops, which have done duty on wool bales, and which, with the aid of ‘‘a patent button,’’ are regularly sent out to Mr. Lloyd’s packers in Algeria and Spain. The paper trade in all branches is important; but the making certain kinds from Esparto and straw is, in relation to progress, the most influential of all.

Lloyd‘s paper mills, at Bow, have been established since 1860. They have been growing steadily and still show an elasticity which promises further expansion. There are about 200 hands employed. I am also happy to find these employées of a very good type; in fact, the whole place is orderly, the people at work are attentive, and the mill is most ably conducted by a manager, whose venerable appearance and general bearing offer an assurance that all goes well. In addition to Esparto and straw, there are piles of old ledger covers in one place, and mountains of old letters and envelopes in another, all of which, in some shape, find their way into paper, either suitable for wrapping or for printing. In going over the premises, I observed that, by the aid of machinery, the knots are taken out of wheat straw before it gets into one of the revolving boilers, into which all straw materials must go, as a first process. Oat straw is too valuable for fodder to be used in paper making. But seeing the demand for paper is so great, it is well that there are so many fibres to be had. If flax crops were cultivated with that energy in the United Kingdom with which Mr. E. Lloyd has prosecuted the gathering and utilising of Esparto, there might be a considerable portion of a second quality of scutching tow available for paper making. All idea of using shoves has long since been dissipated, yet there are certain things wasted at scutch-mills which, if in sufficient quantity, would certainly be of use in paper making. There is no reason, therefore, to despair of getting supplies from flax refuse, provided only it were more largely grown and more scientifically scutched. But it is likely that when flax fibre is employed in paper making it will compete with rags, and not Esparto or straw. In the boiling process the pressure is very high, and much depends on the preparation of chemicals with which the water is charged. In these matters Mr. Lloyd has ever been a man of progress, as every apparatus in use in the mill shows.

It is very interesting to follow, as I was permitted to do, the pulp through all its stages, till it becomes paper. I do not attempt a description of these processes, as paper-making has been so often described already, and that made from straw and Esparto, at Mr. Lloyd's mill, has been noticed at length in several of these descriptions. But as I passed along I could not but pay attention to the easy and efficient methods adopted for cleansing the pulp, washing it as it approaches towards paper, letting the dirty water escape, and keeping such as contains valuable chemicals. The blue used here for clearing the tone of white papers is made in East London. But this has been noticed in Chap. IV. The process of converting straw into paper depends much on chemistry. But a wood pulp has already been produced by mechanical means instead of chemicals. Tints get into paper while it is in pulp and wet. The machinery at work at this mill is remarkably well kept, and the best of its kind. There are several engines and some four or five boilers. One of these is being fuelled by one of Dillwyn Smith’s mechanical stokers. This is a most ingenious contrivance, and though it saves coal and lessens labour, it also economises heat, as no cold air can get in while the boiler is being coaled. Appliances are visible all over the premises for the lessening of manual toil and elevation of industrial labour. The system of machinery at work is the best of its kind, and evidently capital has been invested with no miser's reserves in getting up every part of the Works. There is a reservoir which covers an area of probably between an eighth and fourth of an acre constantly full. The water as it comes from the River Lea is full of earthy matter, which rapidly finds its way to the bottom, from which one deposit or another has to be cleared out. This water is purified by passing over stones, and at last finds its way filtered into tanks, from which it is pumped into the several parts of the Works in which it is required. Even these storing and filtering appliances prove that no cost is spared, and no pains considered too much in doing everything attempted in the best possible way. The amount of money at stake here is very large. Therefore, together this mill is well worthy of a place amongst the chief of East London Industries.

I must not, however, pass over what I take to be the most important feature of the Works, namely, the Hoe machine, which is here at work. I am happy to find that I am justified in holding this opinion by no less unquestionable authority than Mrs. Brown, who, having visited the Works in 1870, was struck by a sight of the ‘‘O printing macheenes,’’ and says: ‘‘Why they makes the paper by the miles here for Lloyd’s News, then they cuts it up into bits for the machine to turn into fires, and murders, and baby farmers’ triels.’’ Now, I should take leave to add that there are miles of paper made here for other journals, both in London and the provinces, as well as Lloyd’s. Also that Mr. Lloyd was the first to adopt the machine which admits of the reel instead of sheets of paper in printing. The advantages of this machine is obvious, even to one unacquainted with the trade. The same amount can be done by it as is done by Hoe’s machine, which does not admit the reel; and the doing of it requires only three men instead of sixteen. Perhaps there is no fact more important than that progress owes a great deal to invention, but it owes more to the enterprise of capitalists.

I regret, after all, I have not had space to describe the paper-making process as I find it here. But I feel that, interesting as such information would be to many readers, it must be much more so to learn that invention and capital have certainly combined all over East London, and in no place is there a more striking instance than the one before me. I must not close this portion without mentioning that when I visited this place a new strainer was on trial, in the last process of paper-making. Also that sometimes twenty-four miles of paper is reeled without a break. The woollen felts used have found a rival in cotton fabric, which I am told promises great things. The reeling process is a most interesting one, and the use of the indicator, marking lengths, is a striking feature. There is a machine and fitting-shop attached to the mill, and taking the paper-making, printing, and every other process, as a whole, the Works of Mr. Lloyd, at Bow are amongst the most important, in a commercial and industrial sense, in East London, and probably are as well managed as any other in that division, or elsewhere in or out of the metropolis.

Footnotes

- 1 Glenny Crory, W. East London Industries (London: Longmans Green & Co, 1876).