Sittingbourne

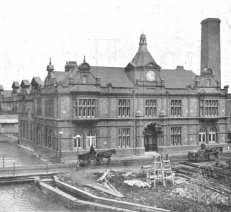

Lloyd’s paper mill at Bow was a great success, but in the early 1860s the demand for paper was imense, so in 1863, Lloyd went on to buy an old paper mill at Sittingbourne in Kent. It was ideally placed with plentiful fresh water and easy access for sea-going shipping. His agent stored straw there, and fire destroyed the mill later that year.1

|

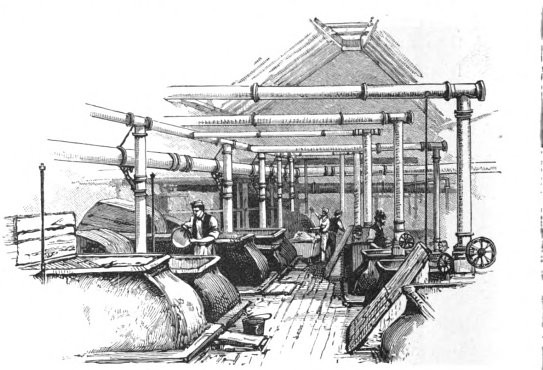

| Beating machines at Sittingbourne Mill. |

|

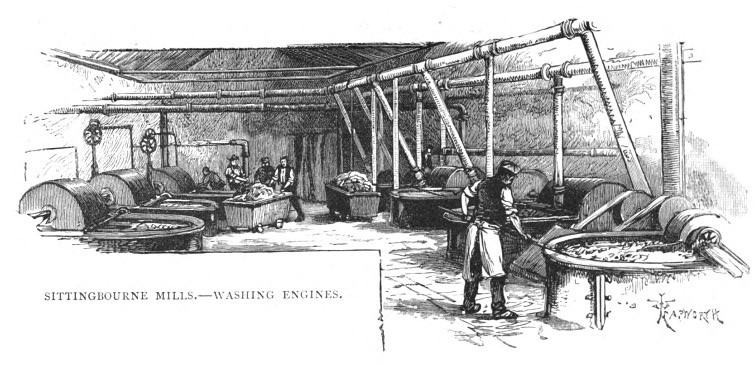

| Rinsing machines at Sittingbourne Mill. |

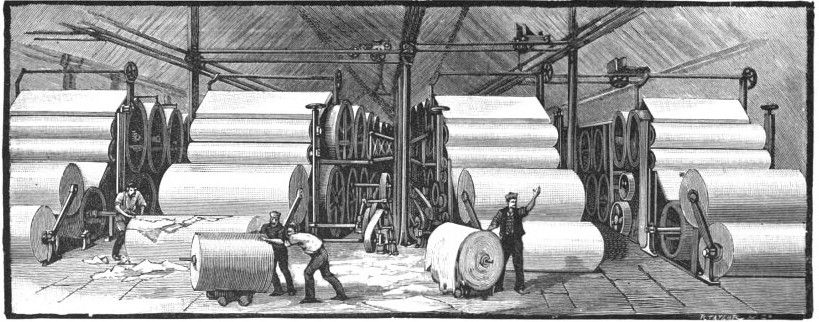

In 1876, Lloyd installed a machine 123in wide at Sittingbourne, built for him by George and William Bertram of Edinburgh.2 This giant caused consternation, and even some misgivings on the part of George Bertram, but Lloyd’s judgment was vindicated and the machine was a great success.

|

| Paper-making machines at Sittingbourne Mill. |

In 1877, he imported a 126in machine from the US. This marked the final move from Bow Bridge and coincided with the transformation of the Daily Chronicle into a national newspaper. At some point after 1877, the mill at Sittingbourne was renamed The Daily Chronicle Paper Mill.

Lloyd continually experimented with anything that contained fibre. North African dwarf palm was being used in 1880, but it was dropped, possibly due to the cost—£8 to £10 a ton (whilst esparto still cost as little as £3). Hemp and waste paper were among the other raw materials used. In 1875, Crory expected home-grown flax to take over the English market, but that never happened. Both flax and esparto are suitable for the finer types of paper.