History of Paper-making

In essence, the process of making paper has changed little since it was conceived in first century China. What changed in the 19th century was the speed of production. In 1800, the manual process would have been measured in seconds per sheet. From 1827 to 1902, this rose from 25ft to 550ft a minute — a 22-fold increase. Acceleration to the present day was merely tenfold, albeit reaching an astonishing mile a minute.

The process

The raw material first has to be reduced to pulp. Almost any material derived from plants contains cellulose fibre but not all is equally good for making paper. Cotton and linen rags, originally plant fibre, were virtually the only source used in the manual trade. These rags were soaked, fermented, washed and then beaten to shreds by stamping-mills. These consisted of rows of great wooden hammers caused to rise and fall by means of a series of cams on an axle driven by water power.1 The “Hollander” beater gradually replaced the original stamping-mills after its invention in 1690.

Paper moulds are then dipped into the vat of pulp to capture a layer of fibre, the nascent sheet couched onto felt, pressed, stacked without the felt, pressed again and then dried. Output from this process is necessarily in sheets and speed limited by the human factor. The size of a sheet was also limited to the arm span of the paper-maker.

The Fourdrinier Machine

Before 1800, all paper was still made by hand and there were some 640 mills in England, Scotland and Ireland.

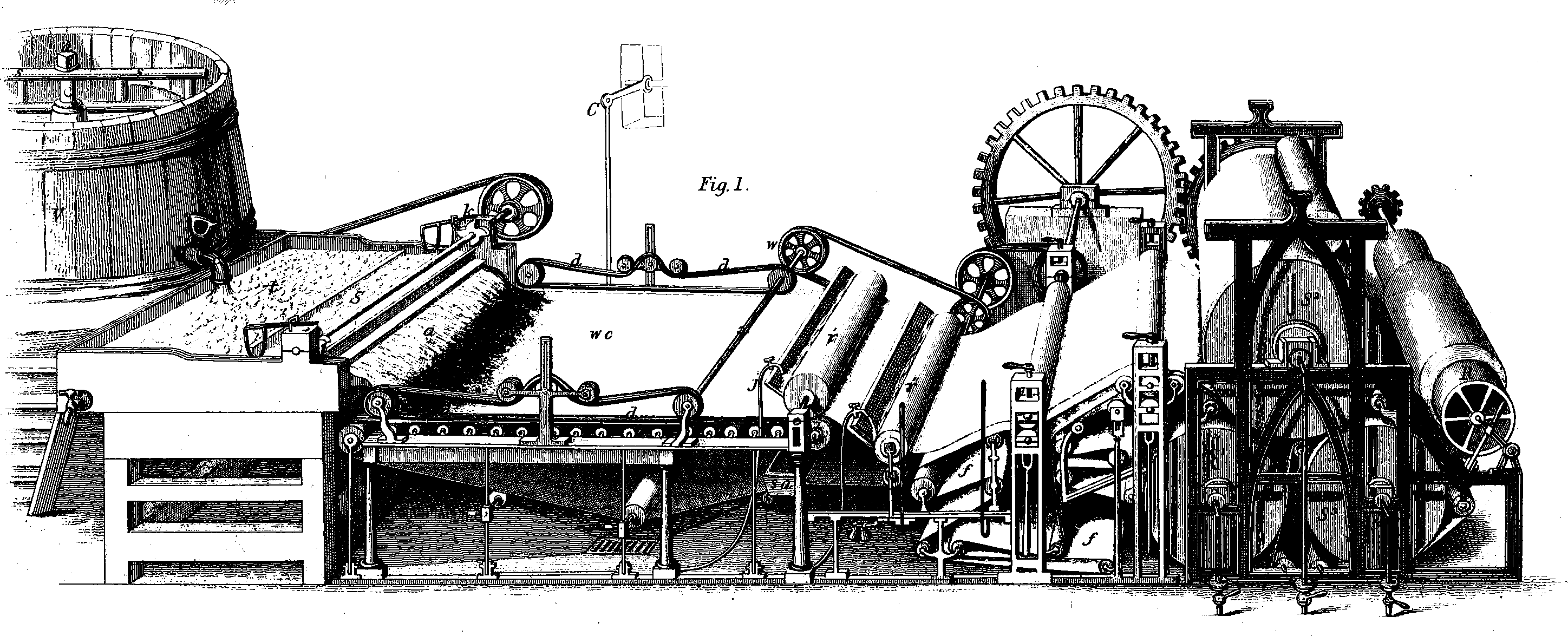

|

| Foudriner paper making machine. |

In 1799 the first attempt to produce paper in an endless web was made in France by Nicholas Louis Robert an employee of Saint-Léger Didot, a papermaker in Corbeil-Essones, near Paris. The invention was brought to England by Didot's brother-in-law, John Gamble, in 1801, and made the subject of patents, which in 1804 were assigned to Henry and Sealy Foudrinier. Bryan Donkin, the engineer, carried out the plans and produced a working machine with a screen moving mechanically on a loop that would perform the function of straining the fibre from the liquid in the vat to make a single continuous stream of paper.2

The first British mill to use the mechanised process was in Frogmore, Hertfordshire, in 1803. Development costs rose to £60,000 and this was largely borne by the two Fourdriniers, who went bankrupt in 1812. As litigation followed, a substantial record of their business survives.

They never gave up on a promise given by Parliament on extension of their patent that they would be compensated for royalties lost because of the law’s shortcomings. Emperor Nicholas of Russia had failed to pay any of the royalties set at £700 a year for ten years on two machines supplied in 1814. After powerful pleas from Mr Lawson of The Times and Marc Brunel, pointing out how much paper duty revenue had been collected thanks to the productivity of the Fourdriniers’ machines, Parliament voted in 1840 for a payment of £7,000 to be made to the Fourdriniers.

Lloyd’s Papermaking

When Lloyd started making paper, rags were in short supply and he started to use esparto grass imported from Algeria. The grass must be made into a usable pulp by cutting it into small lengths and washing it to remove any detritus. It must then be treated with a strong alkali to remove the lignin, part of the plant's structure that turns yellow with time. This makes the process more complicated and uses more water than the traditional use of recycled cotton or linen rags. Lloyd had paper mills first at Bow Bridge on the river Lea in London and later at Sittingbourne in Kent.

A short summary of the operations at Sittingbourne can be found in A Glimpse at Paper Making, an Edward Lloyd Ltd souvenir for visitors to the British Empire Exhibition in 1924. The process at Lloyds is described at greater length in an article in The Paper Maker and British Paper Trade Journal, November 1902. Drawings of the machinery at Lloyd’s Bow Bridge mill can be found in The Engineer, 26 July 1867, and a collection of photographs of Sittingbourne was compiled by F M Rammel, a local photographer.