History of Paper-making

In essence, the process of making paper has changed little since it was conceived in first century China. What changed in the 19th century was the speed of production. In 1800, the manual process would have been measured in seconds per sheet. From 1827 to 1902, this rose from 25ft to 550ft a minute — a 22-fold increase. Acceleration to the present day was merely tenfold, albeit reaching an astonishing mile a minute.

The process

The raw material first has to be reduced to pulp. Almost any material derived from plants contains fibre but not all is equally good for making paper. Cotton and linen rags, virtually the only source used in the manual trade, were plant fibre originally.

In Lloyd’s case, he had first to reduce esparto grass to a usable pulp by cutting it into half-inch lengths and washing it to remove any detritus. He also had a machine that separated and discarded the knots from the stems of straw. Wood that had already been ground into pulp went straight to soaking and bleaching.

Mechanised production only departed from the traditional method by adding the fifth step:

- Boiling, beating and maceration to separate and suspend the cellulose fibre in water, with addition of chemicals and other substances to remove impurities, improve opacity, reduce ink absorption, de-ink waste paper etc (“wet end”)

- Filtering to form a matted sheet of fibre (“forming section”)

- Pressing and compacting the wet sheet to squeeze out the water (“press section”)

- Evaporation of the remaining moisture (“drier section”)

- Feeding of the dry sheet, with any additional treatment such as coating, on to reels (“calendar section”)

The first step softened the fibres and a mild acid solution was added to remove the lignin that bound them together in the original material. This liquid was then put through a processor that churned it and cut the fibres further. The result was strained to catch and discard any bits that had got through the process so far.

It was then poured over an extremely fine mesh which strained it to extract only the fibre. As Henry Massingham (p.141) put it, it was poured, “a milky mass, on to a bed of very fine wire with a tremulous lateral movement which shakes the loose fibres together. The water is then sucked off in vacuum boxes underneath the bed, and in a second, as it were, you can see the little milk-white river harden into the roll of virgin paper — ready for the press.”

It still had to pass through pressing rollers to extract any remaining water and heated rollers to dry it before it was fed on to reels. Lloyd rerolled these to check quality before sending them down to the docks for dispatch to the London press or beyond.

A short and accessible summary of Lloyd’s operations at Sittingbourne can be found in A Glimpse at Paper Making, an Edward Lloyd Ltd souvenir for visitors to the British Empire Exhibition in 1924. The process at Lloyds is described at greater length in an article in The Paper Maker and British Paper Trade Journal, November 1902. Drawings of the machinery at Lloyd’s Bow Bridge mill can be found in The Engineer, 26 July 1867, and a collection of photographs of Sittingbourne was compiled by F M Rammel, a local photographer.

The Fourdrinier Machine

In 1800, all paper was still made by hand with some help from wind and water mills. There were 640 in England, Scotland and Ireland. The papermaker was still called a “stationer”.

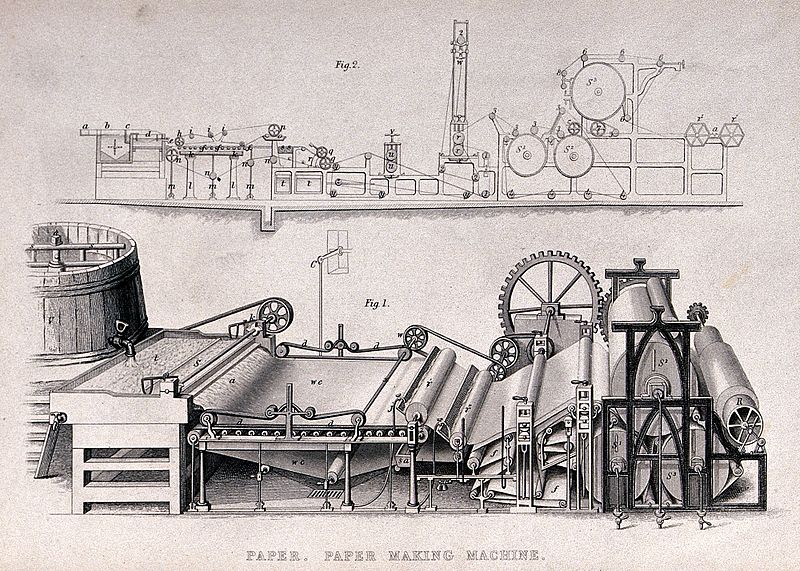

|

| A Fourdrinier paper-making machine. |

Linen and cotton rags, the main raw material, were soaked, washed and beaten to shreds. The “Hollander” machine, invented in 1690 and driven by wind power, was the main technological progress. The bars that beat the fabrics were sometimes faced with iron spikes.

Screens were lowered into the vat of liquid to capture a layer of fibre, moved horizontally to even out the surface, stacked between felt sheets, pressed, stacked without the felt, pressed again and then dried. Output from this process was necessarily in sheets and speed was limited by the human factor. As the industry mechanised, the number of mills halved but capacity expanded vastly.

The mechanical process is called the Fourdrinier process after its English developers, but the Robert process would have at least as good a claim.

Nicholas Louis Robert worked for Saint-Léger Didot, a papermaker in Corbeil-Essones, now an outer suburb of southern Paris. In 1793, the workers made trouble when Robert, a former soldier who did not believe in disorderly goings-on at work, was temporarily put in charge. The experience made him think about less labour-intensive methods.

His solution was to have a screen moving mechanically on a loop that would perform the function of straining the fibre from the liquid in the vat to make a single continuous stream of paper.

Didot, who had previously been irritated by Robert’s penchant for invention (he had created the first hydrogen-filled balloon in 1873), supported him once he could see that the invention was a good one. After initial setbacks, Robert obtained a French patent for a working model in 1799.

The result may have an even better claim to Gutenberg status for its contribution to the dissemination of knowledge than the rotary press.

Circumstances in France were not propitious for development in the 1790s, so Didot wanted to develop the invention in England. He gave his brother-in-law, John Gamble, the patent drawings to take to London. Gamble secured an English patent for it in 1801.

Didot promised to pay Robert F25,000 but defaulted on the instalments. Robert sued him successfully for return of the French patent, but that did him little good. He became a school teacher and died in poverty in 1828.

Gamble sold the English patent to Henry and Sealy Fourdrinier, descendants of Huguenot refugees who ran a prosperous firm of paper merchants in London. They installed a French prototype in Dartford at a mill owned by John Hall. Their contribution to the art was critical — extension of a wire screen to form the paper and to start the draining and drying process, concluding in two revolving cylinders lined with felt to squeeze the paper. This is still in use, referred to as ”the wire” despite having been made of plastic for 30 years.

The first British mill to use the mechanised process was in Frogmore, Hertfordshire, in 1803. The Fourdriniers commissioned Bryan Donkin, a talented engineer who later worked with Marc Brunel on the Thames Tunnel, to make the machine. That was patented in 1806.

Development costs rose to £60,000 (£4.2m now). This was largely borne by the two Fourdriniers, who went bankrupt in 1812. As litigation followed, a substantial record of their business survives.

They never gave up on a promise given by Parliament on extension of their patent that they would be compensated for royalties lost because of the law’s shortcomings. Emperor Nicholas of Russia had failed to pay any of the royalties set at £700 a year for ten years on two machines supplied in 1814. After powerful pleas from Mr Lawson of The Times and Marc Brunel, pointing out how much paper duty revenue had been collected thanks to the productivity of the Fourdriniers’ machines, Parliament voted in 1840 for a payment of £7,000 (£637,000 now) to be made to the Fourdriniers.

The only person who clearly did well out of this was Gamble. He was paid £15,000 by the Fourdriniers for the patent and went on to do business with Bryan Donkin. As Donkin, Hall and Gamble, they pioneered the metal canning of foodstuffs. That company merged with Crosse & Blackwell in the mid-19th century. It was bought by Nestlé in 1960 and sold to Princes Food & Drink Co in 2011.